Thermographic Solar Panel Inspection

Are you curious if your solar panel system has hidden defects that are not immediately visible? A thermographic solar panel inspection maps them out so you can increase your efficiency and avoid unnecessary costs. At Solarco, we deploy advanced thermal imaging technology to thoroughly examine your installation, both for private and large-scale projects.

What is thermographic solar panel inspection?

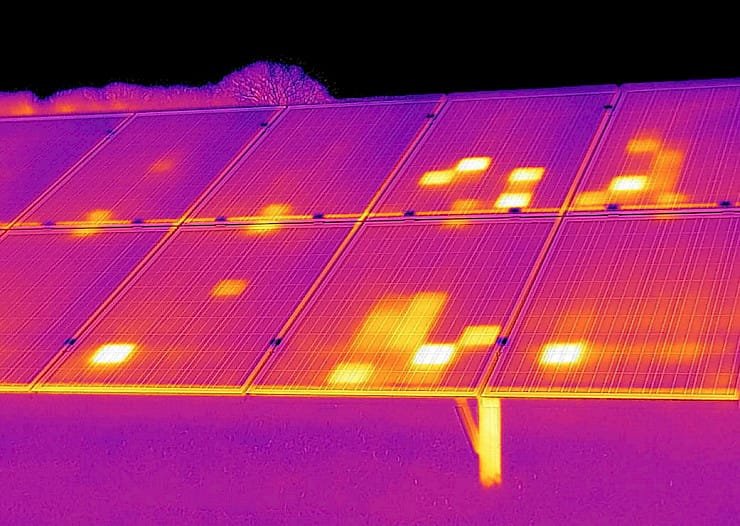

Thermography uses infrared cameras to image temperature differences. If a certain part of a solar panel is warmer than the rest, it may indicate a defective cell, a hot spot or dirt accumulation. These temperature deviations are often not visible to the naked eye but can lead to yield loss and, in severe cases, permanent damage.

A thermographic solar panel inspection will give you a detailed insight into the operation of each panel. Any problems can be detected early on, allowing you to take timely measures such as repairing or replacing panels, thus keeping your energy production on track.

Why is a thermographic inspection important?

- Detecting invisible flaws: Many panels look fine on the outside, while a defect lurks inside. With thermography, you can immediately see where things are going wrong.

- Preventing hotspots: Hotspots are localised overheating that can greatly reduce panel life and even pose safety risks.

- Optimising returns: Small defects can cause big yield losses. By fixing them in time, you get the most out of your investment.

- Cost savings: Replace or repair only what is really necessary. With targeted information from the solar thermal inspection, you avoid unnecessary work.

How does Solarco proceed?

Performing Thermography

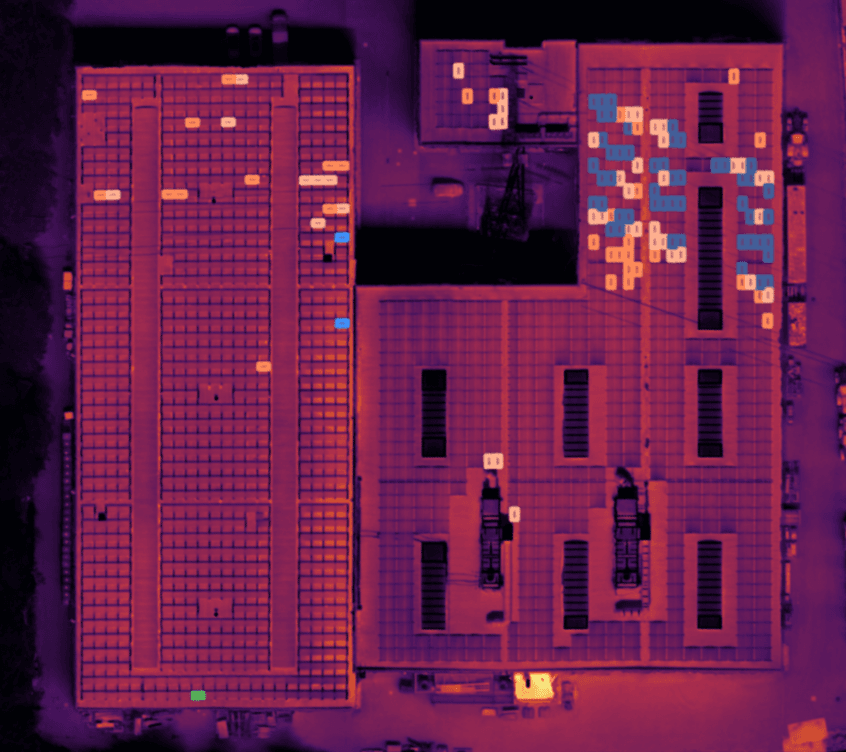

We use professional infrared cameras to take images of the panels. This can be done with handheld equipment or, in the case of large solar parks, with drones that scan a large area in a short time. The images clearly show which panels have abnormal temperature zones.

Analysis and reporting

Our experts carefully analyse the images and identify any hotspots or defects. We process our findings in a clear report with photos and explanations. You will also receive advice on possible repairs, maintenance or replacement.

Possible follow-up

Does the thermal solar panel inspection reveal panels with faulty cells or other defects? Then, if required, we can immediately proceed to repair or replace them. This ensures a quick and effective solution.

Frequently asked questions about thermographic solar panel inspection

Is thermography harmful to panels?

No, the inspection is performed externally with an infrared camera. No direct contact or dangerous radiation is involved, so your installation remains completely undamaged.

How long does a thermographic inspection take?

It depends on the size and accessibility of your installation. A small-scale roof system can be inspected within an hour, while a large solar farm may take several hours.

What if a defect is found?

We will inform you immediately and advise you on the best solution. Depending on the severity and nature of the defect, we can repair on site or schedule a follow-up appointment.

Companies we work with

These companies already rely on Solarco as their regular maintenance partner for their solar panels.