TL;DR

Contamination on solar panels not only costs kWh, but also disrupts load, inspection results and lifespan of your PV assets. This article shows why rain and ad hoc cleaning are rarely enough in professional environments.

- Typical yield losses are around 2-6 per cent, in heavier environments 5-15 per cent, with local peaks of up to around 20 per cent.

- Uneven contamination causes hotspots, additional thermal stress, accelerated degradation and distorted thermography and IV measurements.

- Inspecting for dirty panels leads to misdiagnoses, missed defects and ill-informed maintenance decisions.

- Professional osmosis cleaning is a technical step, not a polish, and is the basis for reliable inspection and reporting.

- A repeatable process of pollution profiling, cleaning, measuring and adjusting makes pollution manageable and maintenance more defensible, supported by tools such as the yield loss calculator and integrated solar panel maintenance.

Contamination solar panel efficiency is often the invisible cause of structural yield losses in professional installations; this article explains in plain language what types of dirt cost efficiency, how quickly it happens and whether rain or ad hoc cleaning is sufficient to prevent kWh losses.

Solar panel pollution and efficiency: what are we talking about?

By “contamination of solar panels”, we mean all external deposits on the glass that directly limit light penetration, e.g. bird droppings, dust and fines, soot and agricultural residues. Such contamination translates into reduced power per panel and thus kWh loss at system level, with the type and location of the dirt strongly determining how much efficiency is lost. It is important for an asset manager to know that small percentage losses translate quickly into euros in medium and large installations, and that annual yield measurements without taking dirt into account can be misleading.

- Bird droppings: hard, localised shadows that heavily affect a single cell or string.

- Fine dust and soot: fine, relatively evenly distributed deposits that structurally reduce yield.

- Agricultural residues and pollen: sticky layers that retain water and promote heat build-up.

In practice, we see that dirty solar panels lose yields of 2 to 6 per cent on average under normal conditions, while installations close to agriculture, industry or heavy traffic can easily lose 5 to 15 per cent, and local pollution such as bird droppings can cause spikes of up to 20 per cent. Rain helps partly wash away loose dust layers, but is often insufficient against sticky residues or mutual disparity in irradiance, so cleaning does make sense for reliable yield data and maintenance planning; for an overview of measured values and example cases, see Dirty Solar Panels Loss of efficiency: is cleaning worth it?.

Aim of this article: looking beyond yield loss due to pollution

This article is written for professional operators who want to look beyond the direct kWh loss due to dirt on their panels and place pollution solar panel yield in the broader context of risk, lifetime and inspection reliability. Around contamination and yield, the discussion often goes no further than 3 or 5 per cent less production, while the underlying stress on cells, connectors and inverters is barely considered; we show how dirt causes local overload and thermal stress, how that distorts the interpretation of measurements and thermographic images, and how this keeps incipient failures out of the picture, so that as a facility, maintenance or asset manager, you can underpin your maintenance decisions with a complete picture of your technical assets instead of reacting ad hoc to visible dirt or annual yield alone.

A second goal is to make it clear that professional cleaning is not a cosmetic polish, but a necessary step to make inspections, IV measurements and drone thermography reliable. First clean, then measure objectively and only then decide on maintenance and investment, that is the maintenance logic that fits with professional asset management and reliable reporting to management or ESG auditors, whereby pollution solar panel efficiency has a place in a broader maintenance plan in which cleaning, inspection and general solar panel maintenance be aligned so that every euro of maintenance is more accountable based on measurable data rather than assumptions that rain will be enough.

Pollution is not an aesthetic problem: impact on efficiency and load

In a photo, a few streaks of dust or a few specks of bird droppings seem mainly an aesthetic problem, but in reality you are affecting both direct yield and the internal load of your installation. Dirty solar panels impact plays on three levels simultaneously: less light reaches the cells, the temperature distribution over the panel gets disturbed and the electrical load per cell changes, which in time amplifies wear and tear; dirty solar panels efficiency therefore not only goes down in percentage terms, the installation also starts to work more thermally, which increases the likelihood of failures and accelerated degradation and, in large portfolios, is felt in failure rates, warranty requests and unexpected replacements.

Types of pollution and their impact on light incidence

Not every type of pollution affects panels in the same way, and for asset managers, that nuance is important to correctly estimate pollution solar panel efficiency. Hard contamination such as dried-out bird droppings acts like a real shadow, blocking light almost completely on one part of the cell, placing a relatively heavy load on that cell, while particulate matter, soot and traffic or industrial dust create a thin more or less even layer over the glass that provides a more even but structural reduction in incident light, and agricultural residue, pollen and spray mist often form a sticky film that not only takes away light, but also retains more heat and reduces water run-off, with consequences for dirty solar panel temperature and thermal cycling.

- Bird droppings locally block almost all light and cause harsh shadows on some cells.

- Fine dust and soot uniformly reduce the overall light level, causing structural yield losses.

- Agricultural residues and pollen form a sticky layer that takes away light and promotes heat build-up.

In combination, these types of dirt determine how much net light still falls on the cells and where temperature peaks occur, and thus how much solar panels cost dirt efficiency and lifetime; installations at farms or along highways therefore have a different pollution profile than an office roof in a quiet environment, implying that the optimal cleaning frequency is not the same everywhere, and guidelines from residential context are of little use for professional roofs and solar parks, so it is better to link pollution and yield data and determine or re-evaluate a maintenance frequency based on that, for example using insights such as those described in how often to clean solar panels.

Real-life examples: bird droppings, particulates and agricultural residues

In practice, we see that a single strand of heavy bird droppings on a corner panel can already cause noticeable yield loss and local hotspots, while the overall string production still looks acceptable in your monitoring dashboard. In aerial photos of solar parks along railway lines and busy roads, the effect of fine dust and soot is clearly visible as a grey veil, which translates into an even but persistent drop in dirty solar panel yield loss across all strings, while on agricultural roofs, lanes of manure or feed residue along ridges and vents are often visible, running across the panels like thermal ribbons and causing a combination of light loss and heat concentration.

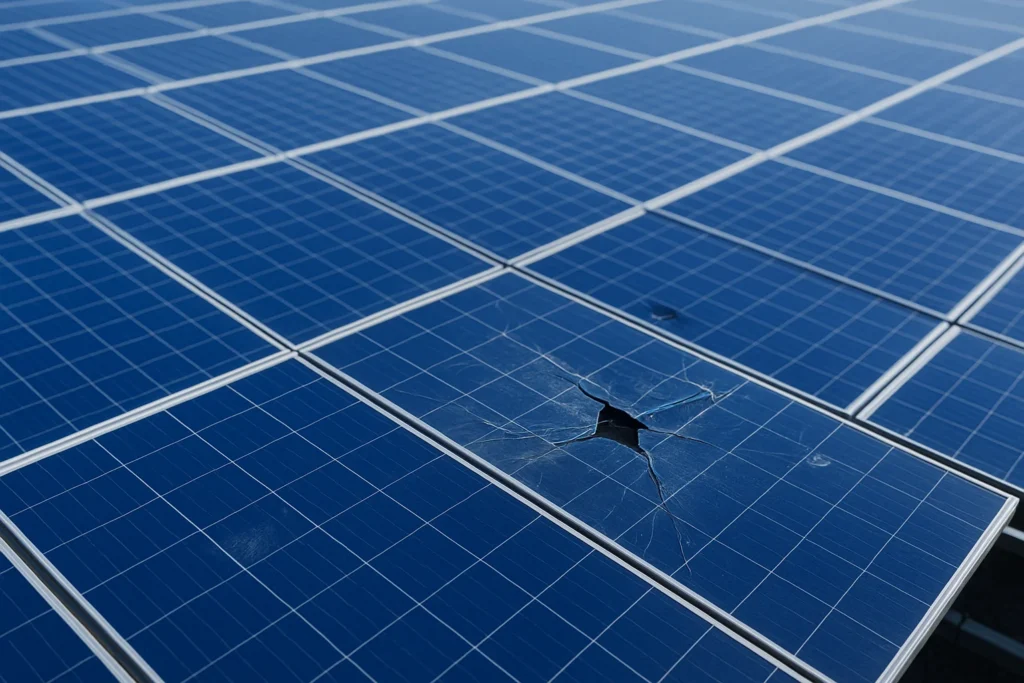

In each of these scenarios, it is striking that the problem only really becomes visible when panels are thoroughly cleaned and then assessed with thermography or detailed measurements; damage caused by years of local overload, such as discolouration and incipient hotspots, is only distinguished from temporary dirt when the top layer is gone and the underlying cell structure comes clearly into view, so anyone who regards dirt mainly as an aesthetic factor and counts on rain or occasional cleaning with, for example, solar panel cleaning with garden hose or a simple Solar Clean set underestimates how strongly solar panel dirt can structurally affect efficiency and technical load.

From pollution to failure: how loss of efficiency causes technical damage

Pollution solar panel efficiency may seem like a percentage yield story in the short term, but in the longer term it is mainly about how uneven shading physically stresses cells and components. In each module, cells are in series, which means that the weakest or most shaded cell helps slow down the rest and creates internal stresses; when this happens frequently and for long periods, bypass diodes are triggered, localised heat spots are created and the problem shifts from simple contamination to real technical damage via many cycles of thermal and electrical stresses that occur especially where dirt accumulates.

Shading, bypass diodes and local thermal stress

Uneven contamination creates mini-shaded areas at cell level, for example where bird droppings or a persistent stain of agricultural residue completely covers the glass, leaving the affected cells barely supplying power while the rest of the cell string in that panel does try to operate at full power, and voltages and currents distribute differently than intended in the design. Bypass diodes, built in to temporarily bypass a group of cells in heavy shade, then periodically kick in and electrically sideline that part of the panel, resulting in localised heating, so that this repeated thermal loading around the shade spot creates hotspots, increases temperature differences within the module and causes the material to expand and contract faster than clean, evenly shaded panels.

For non-technical managers, it helps to think of bypass diodes as automatic diversions in a road network that are activated as soon as a lane becomes blocked by dirt or shade; one bypass required occasionally causes limited damage, but when the same route becomes congested day in and day out due to recurring pollution, cracks in the asphalt and accelerated infrastructure wear occur, which in solar panels translates to micro-cracks in cells, accelerated degradation of joints and a higher likelihood that a slight manufacturing tolerance or manufacturing defect will grow into a permanent defect, with dirt often becoming the trigger that accelerates existing weaknesses to the surface.

Accelerated degradation: microcracks, hotspots and longevity

Microcracks are small cracks in the solar cells or in the connections between cells that often remain invisible on initial visual inspection and only come to light during specialised inspections, and in a clean, evenly loaded installation, such microcracks can remain relatively stable for years without noticeable impact on pollution solar panel efficiency. Under repeated hotspots caused by dirt, however, the likelihood of them expanding into actual cracks increases, as the combination of thermal stress, elevated operating temperatures and irregular power distribution accelerates cell degradation and can lead to persistent hotspots that remain visible in thermographic reports even after cleaning, so that installations with structural fouling not only show lower yields but also surrender parts of their technical lifespan faster.

It therefore makes sense for asset managers to look at pollution not only in terms of annual kWh losses, but also in terms of accelerated ageing and future replacement costs. A panel that runs structurally under dirt and hotspots for 10 years is expected to fail sooner or at least drop below an efficiency threshold sooner than a similar, well-maintained panel, so measuring how pollution affects solar panel efficiency and linking that to inspection data on microcracks and hotspots gives a more realistic picture of the real TCO of the installation and makes professional cleaning a management measure to mitigate technical risks and lifetime losses rather than an intervention just to get the next annual yield slightly higher.

How pollution disrupts solar panel efficiency and inspections

Inspection results only become truly reliable if measurement conditions are controlled and reproducible, and that is precisely where dirty installations falter. Dirt affects both the optical and thermal properties of a panel, which has direct implications for inspection solar panel thermography, IV measurements and classic visual checks; those who ignore dirt run the risk of reports showing a combination of real technical problems and artefacts due to dirt without making the distinction clear, resulting in doubts about the conclusions, discussions with suppliers and a contaminated picture of the true state of the installation.

Thermography and drones on dirty panels

Thermography, carried out with or without drones, is a powerful tool for detecting hotspots, malfunctioning cells and connections or deformation problems, but dirty panels make interpretation much more complex because dirt absorbs and retains heat differently from clean glass, and dirty areas may therefore appear warmer or colder on images without a real internal defect being present. At the same time, an incipient hot spot under a thick layer of dirt may actually stand out less clearly against its surroundings, so that it is initially missed in the thermography report, which is why professionals try to overcome this by combining thermography campaigns with an estimate of the level of dirt or by scheduling prior cleaning, as described in services such as thermographic solar panel inspection.

In large solar farms where drones are rapidly scanning thousands of panels, the impact of contamination solar panel yield on thermography becomes even greater because the analyst relies primarily on pattern recognition and can create irregular contamination patterns that closely resemble real technical issues, for example hot lanes that actually follow traces of agricultural residue. Conversely, a series of panels with light but systematic fouling in one zone may be less noticeable than a single, very dirty module, while the overall yield impact of that zone is much greater, so without a clear distinction between fouling effects and real defects, it becomes difficult to prioritise inspection advice and target corrective action investments.

IV curves, string analysis and visual inspection under contamination

More classical measurement methods such as IV measurement solar panel pollution and string analysis are also sensitive to uneven irradiance due to dirt; for example, when one string carries more pollution than a reference string, it will structurally provide less power at equal solar irradiance, so comparisons between strings show a mix of dirty and clean effects and in maintenance reports where such measurements are not explicitly corrected for pollution outcomes can lead to unwarranted conclusions about alleged panel or inverter problems or to underestimation of actual dirty solar panel yield losses. Moreover, dirt masks minor discolouration, incipient delamination or hairline cracks in cells during visual checks, meaning potentially relevant clues to future defects are simply not seen.

- IV curves of dirty strings deviate due to uneven irradiation and give a distorted picture of panel health.

- String analyses often compare dirty with clean, making conclusions about efficiency and defects impure.

- Visual inspections on dirty panels miss discolouration, micro-damage and small delamination spots under the dirt.

The upshot is that solar panel inspection reliability comes under pressure once contamination is not explicitly included in the inspection process towards the client; for asset managers, this means that measurement data and reports become less useful for long-term decisions on replacement, warranties and optimisations, so a logical step is to link inspections to a cleaning regime and treat contamination solar panel efficiency as an influence variable in the analysis, with tools such as the dirty solar panels efficiency loss calculator can help to quantify that pollution component separately, thus creating a clearer separation between maintenance issues and real technical defects.

Clean first, then measure: logical sequence for reliable efficiency

If contamination affects both yield and measurement results, the order of action is actually obvious: first clean, then measure and only then decide on possible interventions. That order reverses classical reasoning in which cleaning is seen primarily as a closing item, a cost item that only comes into play when dirty solar panels yields are visibly depressed in the annual figures, whereas in a professional maintenance philosophy, cleaning actually becomes a preparatory technical step, designed to ensure that all panels are functioning under as equal irradiation and temperature conditions as possible at the time of inspection so that pollution solar panel yield is first normalised and inspection data can be interpreted on a much more reliable basis.

Cleaning as a technical step, not a polish

Professional cleaning does not start from the idea that panels must be beautiful, but that light and temperature distribution must be restored as uniformly as possible to allow a correct assessment of the installation, which means working with suitable water and materials, such as soft osmosis water and specially developed brushes, so that glass and coatings are not damaged and seals remain intact. For installations at height or in industrial environments, this is compounded by the need for safe and scalable working methods, with an eye on fall protection, site coordination and minimal disruption to business processes, so that cleaning becomes a full-fledged technical intervention within the maintenance of your solar assets, similar to lubricating moving parts or checking safeguards in other installations, and seamlessly with structured solar panel inspection.

By positioning cleaning as a technical step, it also becomes clear why short actions such as a quick wipe with the garden hose or an occasional polish contribute little to reliable data, because the goal is not to remove every stain but to make the impact of contamination solar panel returns predictable and as small as possible during the measurement campaign, which requires planning and coordination with operations and sometimes timing other than purely aesthetic arguments would dictate. For larger portfolios, this may even mean combining cleaning and inspection into one integrated maintenance round so that decision-makers receive one coherent report instead of separate snapshots.

What professional cleaning does differently from ad hoc cleaning

Ad hoc cleaning with a telescopic brush from the DIY shop, a garden hose or suds with washing-up liquid seems attractive, but rarely does justice to the technical requirements of modern PV installations; solutions such as solar panel cleaning telescope or solar panel cleaning with garden hose often tackle contamination unevenly and leave residue behind, which only temporarily improves contamination solar panel efficiency and increases the likelihood of streaks, calcium stains or even micro-scratches. Agents like Dreft or other household detergents seem harmless, but can corrode coatings, actually attract dirt and in time promote leaks around seals, reasons why specialist parties advise against this approach and explain alternatives in analyses such as Cleaning solar panels with Dreft, especially for professional rooftops and solar parks where guarantees, safety and long-term efficiency weigh heavily.

A professional therefore looks wider than just solar panel cleaning price or the quick removal of visible stains and considers cleaning within the overall picture of maintenance, inspection and reporting, working with demineralised water, controlled pressure, adapted brushes and a sophisticated work plan that takes into account installation type, environment and accessibility. For asset managers, this means that cleaning is not a stand-alone cost, but part of a maintenance pathway designed to manage pollution solar panel efficiency, inspection reliability and technical risks simultaneously, which also ties in with critical questions around solar panel cleaning nonsense, where the answer is usually not black and white but depends on environment, scale and how cleaning is embedded in overall maintenance, as also explained in price and approach overviews such as solar panel cleaning price.

What goes wrong if you inspect without cleaning first

When inspections are carried out on dirty installations, the whole chain from diagnosis to decision-making becomes muddled because measurements then combine the effects of technical deviations and pollution solar panel yield, making it difficult to determine which part of the yield loss is due to real defects and which part to dirty surfaces. In practice, this leads to wrong conclusions, such as wrongly designating certain strings, panels or inverters as problem culprits when the main reason is uneven pollution and, at the same time, real defects sometimes stay under the radar because the measurement deviations due to dirt are bigger than the subtle signals of incipient technical problems that you precisely want to detect early.

- Maintenance decisions are based on unreliable data, leading to unnecessary interventions or replacements.

- Real defects or risks go unnoticed because their signal is hidden among pollution-related anomalies.

- Maintenance budgets are wrongly prioritised, with too much focus on visible dirty areas and too little on structural problems.

For an asset manager of solar panels, this means that it becomes increasingly difficult to justify maintenance costs and to make a clear link between measures taken and improvements realised in yield and availability; structural maintenance in which cleaning and inspection are aligned, as elaborated within broader solar panel maintenance, provides a much cleaner data situation and therefore decisions that are truly based on technical facts, with periodic pollution, yield and inspection results juxtaposed to give a consistent line in reporting and make clear which part of performance is influenceable through maintenance and which part is determined by design, location or age.

From insight to action: managing pollution and yield structurally

Structural management of pollution and yield starts with a clear, repeatable methodology: make pollution profiles, clean professionally, measure clean and decide on data, so that for medium and large installations, even a few per cent yield difference can be translated directly and substantiated into financial impact and cleaning becomes technically embedded in asset management. Organise your process so that cleaning does not become an incidental cost item, but a planned technical step that makes inspections possible and measurement data reliable.

- Establish a pollution profile for each site, with factors such as proximity to traffic, agriculture or industry.

- Schedule cleaning before thermography and IV measurements so that results are interpretable and comparable.

- Use professional methods and certified teams to avoid damage and restore even irradiation.

In summary, a simple, repeatable schedule of profiling, cleaning, measuring and adjusting makes contamination manageable and protects technical efficiency, while tools such as an efficiency loss calculator help set priorities per site and set maintenance frequencies realistically. Contamination solar panel efficiency doesn't just affect kWh, it also affects reliability and lifespan; if you would like this process professionally worked out or a second opinion on your maintenance strategy, please feel free to take contact.

FAQ

How much efficiency do I typically lose due to pollution?

Typically, pollution delivers about 2-6% yield loss. In environments close to agriculture, industry or heavy traffic, this can easily 5-15% are and local pollution (e.g. lots of bird droppings) can peak to ~20%, as described in the article.

Does rain remove enough dirt or should I have it professionally cleaned?

Rain partly washes away loose layers of dust, but is often insufficient against sticky residues (agricultural residues, pollen) and uneven soiling. For reliable thermography and IV measurements, professional cleaning is recommended before inspection.

How often should I clean my solar panels?

There is no set frequency: it depends on location and pollution profile (traffic, agriculture, birds). Work with site profiles, plan cleaning before thermographic and IV campaigns and use tools such as the yield loss calculator To set priorities and frequencies based on financial and technical impact.

Can DIY methods or detergent damage panels or affect warranties?

Improper means and techniques (garden hose, aggressive detergents such as Dreft) can corrode coatings, cause chalk streaks and micro-scratches, and eventually stress seals. Therefore, use demineralised water and specialised cleaning methods or a certified party to damage and warranty issues avoid.

Why is it important to clean before having inspections carried out?

Contamination distorts thermographic images and IV curves: dirt can mask or fake heat patterns and make it difficult to distinguish incipient defects from artefacts. Cleaning first gives you reliable measurement data, making diagnoses, prioritisation and maintenance decisions much more accurate.